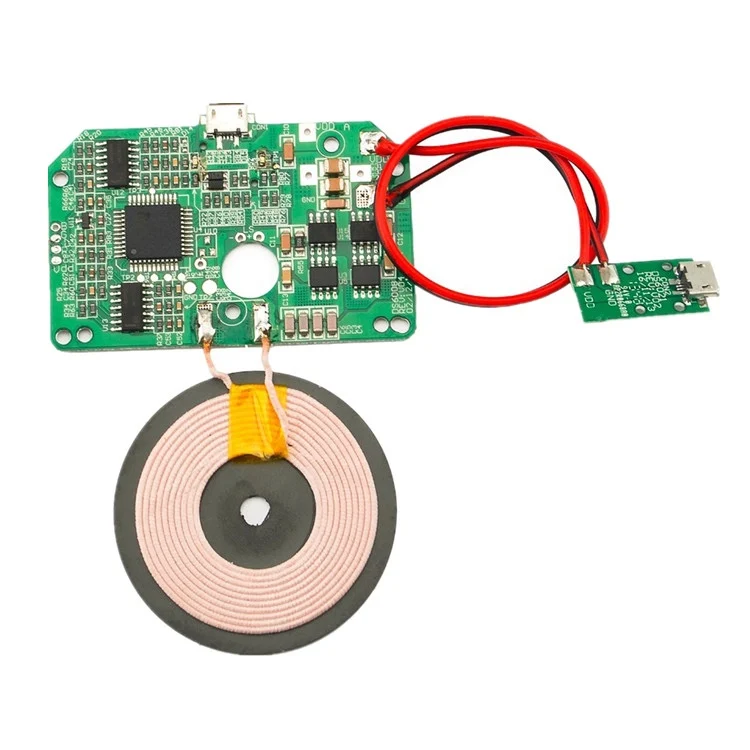

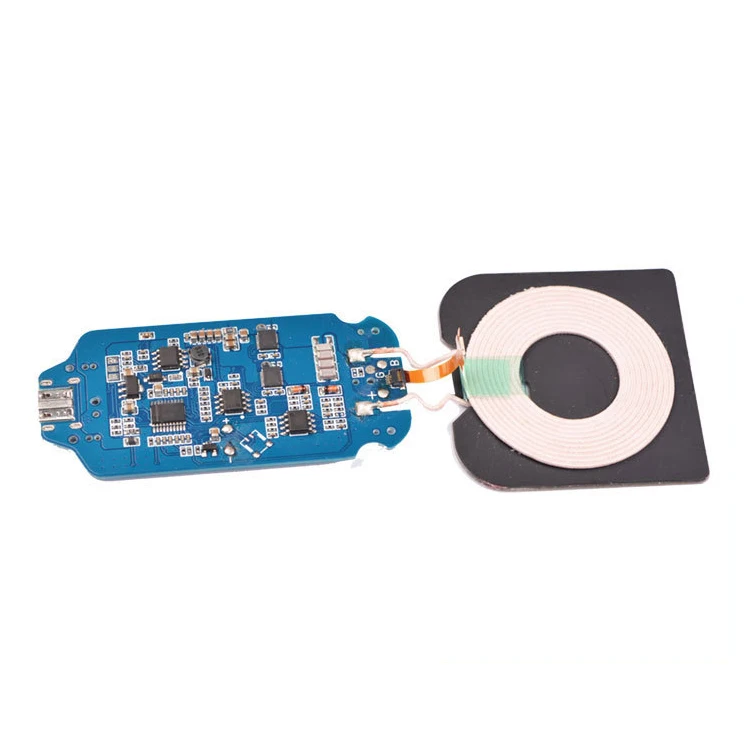

Customized mobile powerbank Wireless Charger PCB

- FOB Price:

- Negotiable | Get Latest Price

- Order Quantity:

- 1 Set / Sets

- Supply Ability:

- 1000 Set / Sets per Month

- Port:

- shanghai

- Payment Terms:

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow Other

- Delivery Detail:

- 5 days

-

Solar Inverter Pcb Green Ink Main Circui

$5.00 -

Customized mobile powerbank Wireless Ch

$9.80 -

FPC for beauty instrument | LHD #PCB

$10.00 -

12 layer PCB with step gold fingers

$10.00 -

0.4mm thin Fr4 PCB Board |LHD PCB

$5.00 -

Thin Antenna FPC Board |LHD PCB

$10.00 -

2-18L Rigid-Flex PCB

$1.00 -

16 layer 7.5mm PCB with edge plating

$50.00

Customized mobile powerbank qi Wireless Charger PCB

One-stop OEM/ODM/EMS Services can Meet:

. PCBA, PCB Board assembly: SMT & PTH & BGA

· PCB Copy, PCB drawing / design according to your schematic diagram

· Components sourcing and purchasing

· Quick prototyping

· Plastic injection molding

· metal sheet stamping

· Final assembly

· 100%Test: AOI, In-Circuit Test (ICT), Functional Test (FCT)

· Custom clearance for material importing and product exporting

| Capability - SMT | ||||

| Lines | 9 (5 Yamaha, 2 KME, 2 SONY) | |||

| Capacity | 52 million placements per month | |||

| Max Board Size | 457 X 356mm. (18” x 14”) | |||

| Min Component size | 0201 – 54 sq. mm. (0.084 sq. inch), long connector, CSP, BGA, QFP | |||

| Speed | 0.15 sec/chip, 0.7 sec/QFP | |||

| Capability - PTH | ||||

| Insertion Type | # of Lines | Capacity (points/mth) | Max Board Size | Lead Pitch |

| Jumper Wire | 3 | 6 million | 330x250 mm (13” x 9.8) | 5-30 mm |

| Axial | 3 | 6 million | 457x559 mm (18” x 22”) | 5-20 mm |

| Radial | 3 | 6 million | 457x559 mm (18” x 22”) | 0.36-21.5 mm |

| Wave Soldering | ||||

| Wave Soldering | 2 | |||

| Max board width | 400 mm | |||

| Type | Dual wave | |||

| Pbs Status | Lead-free line support | |||

| Max temp | 399 degree C | |||

| Spray flux | add-on | |||

| Pre-heat zones | 6 | |||

Detailed Terms for Pcb Assembly

|

1 |

Quantity |

Prototype&Low Volume PCB Assembly, from 1 Board to 250,is for specialty, but we can handle orders up to 1000. |

|

2 |

Type of Assembly |

THD (Thru-Hole Device), SMT (Surface-Mount Technology), SMT & THD mixed, Double-sided SMT and THD assembly. |

|

3 |

Solder Type |

Water Soluble Solder Paste, Leaded and Lead-Free. |

|

4 |

Components |

Passives parts, smallest size 0201; |

|

5 |

Bare Board Size |

Smallest: 0.25x0.25 Inches; Largest: 20x20 Inches. |

|

6 |

File Formats |

Bill of Materials Gerber Files Pick-N-Place File(XYRS). |

|

7 |

Type of Service |

Turn-Key, Partial Turn-Key or Consignment. |

|

8 |

Component Packaging |

Reels,cut tape,Tube and tray,Loose parts and bulk. |

|

9 |

Turn Time |

Same Day Service to 10 day service. |

|

10 |

Testing |

X-ray Inspection |

-

Stripped Soft Goose Fe

$3.00 -

plastic ball grinding

$30000.00 -

CAT piston pump 281

$4000.00 -

Droichead Zirconia Plu

$10.00 -

E.max crown, Veneer, I

Inquiry -

ReSiC Beams/plates/bur

$16.00 -

RSiC Slabs Boards Tile

$15.00 -

RSiC Batts as Kiln she

$15.00 -

RSiC Tube by recrystal

$10.00 -

RSiC Kiln Furniture (B

$16.00 -

RSiC Burner Nozzle Fla

$18.00 -

RSiC Beam Support Pill

$16.00 -

RSiC plate Slab Board

$15.00 -

NSiC Tube Pipes by Nit

Inquiry -

used excavator hudraul

$16600.00 -

NSiC Thermocouple Prot

Inquiry -

Stalk Riser Tube for L

Inquiry -

NSiC Ceramic Heater Pr

Inquiry -

RSiC NSiC Ceramic Kiln

Inquiry -

used excavator hudraul

$11500.00

- brand:

- LHD PCB

- Set up shop

- Authorized by Manufacturers & Suppliers online marketplace B2B platform GongWong.com, can provide agency service

- Service Introduction

- Authorized product, Internet cloud promotion service integrating certification promotion and procurement inquiry

- Intelligent website construction

- PC terminal + mobile terminal, create a cost-effective corporate website!