1/5

IADC637 Tri-cone Drill Bit with journal bearing

$2080.00 / piece

1piece (MOQ)

- FOB Price:

- Negotiable | Get Latest Price

- Order Quantity:

- 1 Set / Sets

- Supply Ability:

- 1000 Set / Sets per Month

- Port:

- shanghai

- Payment Terms:

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow Other

- Delivery Detail:

- 5 days

Hot in store

-

Factory Supply Three Cone Bits For OilGa

$1200.00 -

TCI Rotary Cone Rock Roller Drill Bit wi

$2270.00 -

Factory provide high quality TCI rotary

$1580.00 -

IADC637 Tri-cone Drill Bit with journal

$2080.00 -

9 7/8inch 250mm IADC645 Tricone Drill Bi

$1580.00 -

IADC 537 270 MM Factory Supply Tricone R

$1480.00 -

IADC725 tricone Bits For Oil Well Drilli

$1500.00 -

IADC545 TCI rock roller tricone drill bi

$1150.00

Product Details

12 1/4Inch IADC637 Tricone Drill Bit and Three Cone Head with journal bearing on gage protection

.

Description

| Basical Specification | |

|

Size |

12 1/4 inchs |

| IADC Code: | 637G |

| Thread Connection | 6 5/8 API REG PIN |

| Series |

KA Series Elastomer Sealed Bearing |

| Operating Parameters | |

| WOB | 156-373KN |

| RPM | 80-40 |

| Formations |

Hard formation with high compressive strength ,such as hard shale,sandstone,dolomite, hard gypsum,chert,granite,etc. |

Parameter Selection

Types which are not shown in the table can be designed and manufactured according to customer's requirements.

| IADC | Weight on Bit per Inch of Bit Diameter(lb/In) |

Rotary Speed (r/min) |

Cutting Structure | Applications |

| 412/415 | 1000-2000 | 90-120 | Conical on gage and inner rows | Designed for very soft formations with low compressive strength and high friablity such as shale, soft limestone, sandstone, gravel clay, soft dolimite, coal. |

| 432/435 | 1000-4000 | 90-120 | Conical/Chisel on gage, Conical inner rows | Designed for very soft formations with low compressive strength and high friablity such as shale, soft limestone, sandstone, gravel clay, soft dolimite, coal. |

| 532/535 | 2000-5000 | 80-110 | Conical/Chisel on gage, Conical inner rows | Designed for soft formations with low compressive strength and high friablity such as shale, soft limestone, sandstone, interbedded dolomite. |

| 612/615 | 3000-5000 | 60-100 | Conical/Spherical on gage, Conical inner rows | Designed for high compressive strength, medium hard and abrasive formations, such as limestone, sandstone, interbedded dolomite. |

| 632/635 | 3000-6000 | 60-100 | Conical/Spherical on gage, Conical inner rows | Designed for high compressive strength, mudium hard and abrasive formations, such as limestone, sandstone, interbedded, dolomite. |

| 732/735 | 4000-7000 | 60-90 | Spherical on gage, Conical/Double spherical on inner rows | Designed for high compressive strength, hard and abrasive formations, such as granite, limestone, sandstone, dolomite. |

| 832/835 | 5000-8000 | 50-80 | Spherical on gage, Double spherical on inner rows | Designed for high compressive strength, hard and abrasive formations, such as magnetite quartzite, quartzite, granite. |

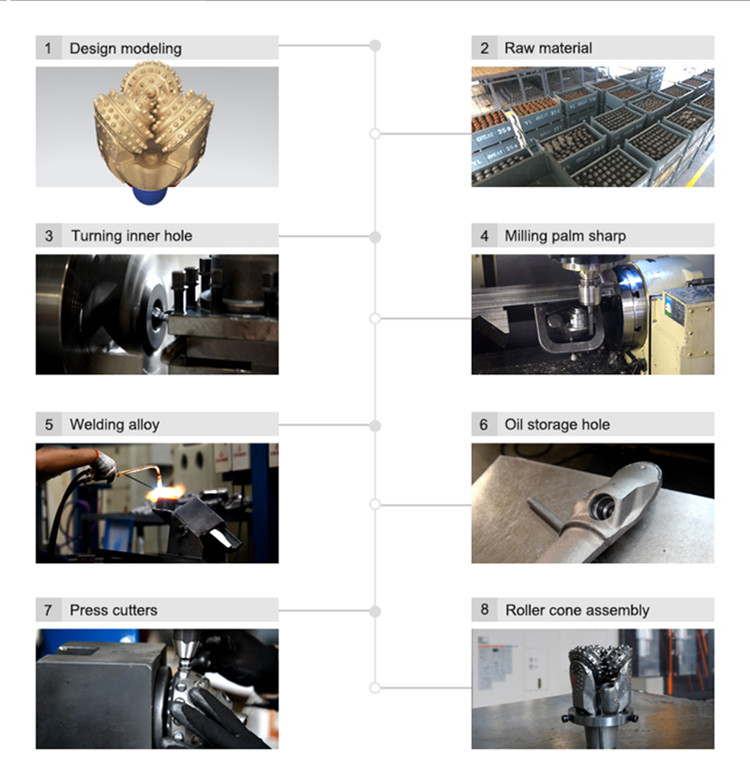

Production Process

Application

Our drill bits are widely used in mining, oil, gas, water well drilling, HDD, quarrying and construction.

Company Information

All of our bits are manufactured according to strict standards, set forth by the American Petroleum Institute (API). And classified according to characteristics set forth by the International Association of Drilling Contractors (IADC).

Hunan TianYing Drilling Machine Manufacturing Co., Ltd. is a professional manufactory of Rock Drilling Bits. Our drilling bits manufacture are based on the extensive research and development in the field of mining. All the Rock Drilling Bits using the finest raw materials available, including Premium Steel and Tungsten Carbide. We ensure that our worldwide clients have quick access to our service, manufacturing and marketing expertise. Our vision is to become the industry's performance leader in tools that withstand the toughest rock drilling demands. That's why our products exceed industry specifications for performance and safety. When you work with TianYing, we are committed to your productivity and efficiency.

Whatsapp:+86 15200507438

Wechat:271811302

Email sales6 at tcidrillbit dot com

Contact with Supplier

Recommend product

-

Stripped Soft Goose Fe

$3.00 -

plastic ball grinding

$30000.00 -

CAT piston pump 281

$4000.00 -

Droichead Zirconia Plu

$10.00 -

E.max crown, Veneer, I

Inquiry -

ReSiC Beams/plates/bur

$16.00 -

RSiC Slabs Boards Tile

$15.00 -

RSiC Batts as Kiln she

$15.00 -

RSiC Tube by recrystal

$10.00 -

RSiC Kiln Furniture (B

$16.00 -

RSiC Burner Nozzle Fla

$18.00 -

RSiC Beam Support Pill

$16.00 -

RSiC plate Slab Board

$15.00 -

NSiC Tube Pipes by Nit

Inquiry -

used excavator hudraul

$16600.00 -

NSiC Thermocouple Prot

Inquiry -

Stalk Riser Tube for L

Inquiry -

NSiC Ceramic Heater Pr

Inquiry -

RSiC NSiC Ceramic Kiln

Inquiry -

used excavator hudraul

$11500.00

Product parameters

- brand:

- Tianying

closure

This shop is operated by agent

- Set up shop

- Authorized by Manufacturers & Suppliers online marketplace B2B platform GongWong.com, can provide agency service

- Service Introduction

- Authorized product, Internet cloud promotion service integrating certification promotion and procurement inquiry

- Intelligent website construction

- PC terminal + mobile terminal, create a cost-effective corporate website!

closure