1/5

F51 FORGED STEEL HIGH PRESSURE BALL VALVE WITH FLANGE END

$0.00

- FOB Price:

- Negotiable | Get Latest Price

- Order Quantity:

- 1 Set / Sets

- Supply Ability:

- 1000 Set / Sets per Month

- Port:

- shanghai

- Payment Terms:

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow Other

- Delivery Detail:

- 5 days

Hot in store

-

Metal Seated High Temperature Trunnion M

Inquiry -

Stainless Steel Industrial Mounted Trunn

Inquiry -

API Cast Steel Globe Valve for Shut-off

$1.00 -

API600/BS1873 Cast Steel A216 Wcb Globe

$1.00 -

BS1868 WCB GLOBE VALVE

$1.00 -

GATE VALVE OS&Y Outside Yoke

Inquiry -

GATE VALVE RENEWABLE SEAT API600

Inquiry -

A216 WCB GATE VALVE FLEXIBLE WEDGE

Inquiry

Product Details

| Size | 2 “ - 48 ” |

| Pressure | ANSI 150LB-2500LB |

| End Connection | Flange RF,RTJ,BW |

| Bore | Full or Reduce Bore |

| Body Material | Duplex & Super Duplex Steel A890 GR.4A,5Aor F51 |

| Ball Material | F51 or customer require |

| Seat Material | PTFE, RPTFE, PEEK,NYLON,PPL Or metal to metal |

| Design | API 6D/ ASME B16.34 |

| Face to Face | ANSI B16.10 |

| End Flange | ANSI B16.5 |

| BW Ends | ANSI B16.25 |

| Fire Safe | API 607 Or API6FA |

| Checking & Test | API 598 |

| Pressure-Temperature | ASME B16.34 |

| Operation | By Lever, By Gear, By Electric or Pneumatic Actuator |

| Suitable Medium | Water,Steam,Oil,and Natural Gas Etc |

| Suitable Temp. | -196 – 540 ? ?Depends on seat material? |

Features

?Three Piece?Full or Reduce Bore

?High Performance Sealing Mechanism

?Fire Safety Design

?Anti-Static Spring Device

?Blow-out proof stem

?Low Emission Design

?Double Block and Bleed function

?Locking Device for Lever Operation

?Low Operation Torque

?Self-relief of Excessive Cavity Pressure

?Zero Leakage

?Working for high temperature up to 540?

Material Specification

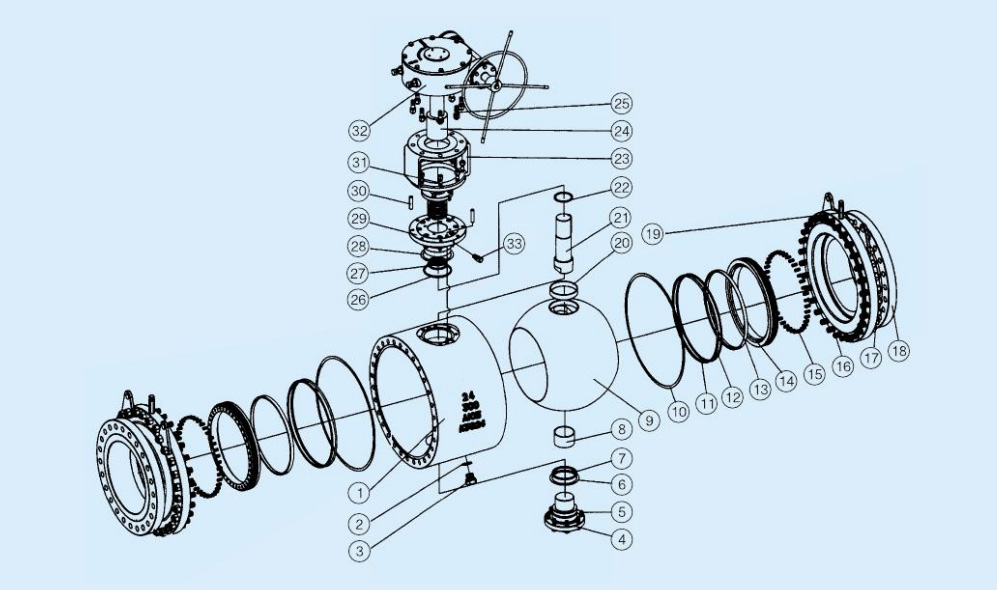

| No. | Name | No. | Name |

| 1 | Body | 18 | Cap |

| 2 | Gasket | 19 | Grease Valve |

| 3 | Drain valve | 20 | Bushing |

| 4 | Bottom Cover | 21 | Stem |

| 5 | Bolt | 22 | Bushing |

| 6 | Gasket | 23 | Yoke |

| 7 | O-Ring | 24 | Sleeve |

| 8 | Bushing | 25 | Bolt |

| 9 | Ball | 26 | O-Ring |

| 10 | Gasket | 27 | O-Ring |

| 11 | O-Ring | 28 | Gasket |

| 12 | Fire Ring | 29 | Bonnet |

| 13 | Seat Sealing | 30 | Pin |

| 14 | Seat | 31 | Bolt |

| 15 | Spring | 32 | Gear |

| 16 | Bolt | 33 | Grease Valve |

| 17 | Nut |

Advantages

1.Forged Body2.Pressure relief valve to avoid cavity over pressure when applicable

3.Emergency built-in stem and seat sealant injection system

4.DBB design enables the use of a single valve with two independently functioning seats on each end of the valve while allowing the cavity between the seating surfaces to be vented or bled.

5.Open and close quickly

6.Self-Relieving Structure

7.Fire safety and Anti-static

8.Locking Device Option

9.Corrosion Resistance

10.Extension Stem Option

More Information

| Payment Term | L/C, T/T, Western Union,Paypal |

| Delivery Time | 15 - 30 days after payment |

| Seaport | Shanghai Or Ningbo China |

| The 3rd Inspection | Available |

| Sample | Available for metal Seat Forged Trunnion Mounted Ball Valve |

| Warranty Period | 18 months after shipments and 12 months after installed |

| Valve Test | 100% quantity tested before delivery |

| Packing | Plywood Case for metal Seat Forged Trunnion Mounted Ball Valve |

| MOQ | 1 Pc for metal Seat Forged Trunnion Mounted Ball Valve |

| Nameplate | According to customer for metal Seat Forged Trunnion Mounted Ball Valve |

| Color | According to customer for metal Seat Forged Trunnion Mounted Ball Valve |

| Shipment | By sea,By Air ,By Express,and door to door available |

| OEM/ODM Service | Available |

Contact with Supplier

Recommend product

-

Stripped Soft Goose Fe

$3.00 -

plastic ball grinding

$30000.00 -

CAT piston pump 281

$4000.00 -

Droichead Zirconia Plu

$10.00 -

E.max crown, Veneer, I

Inquiry -

ReSiC Beams/plates/bur

$16.00 -

RSiC Slabs Boards Tile

$15.00 -

RSiC Batts as Kiln she

$15.00 -

RSiC Tube by recrystal

$10.00 -

RSiC Kiln Furniture (B

$16.00 -

RSiC Burner Nozzle Fla

$18.00 -

RSiC Beam Support Pill

$16.00 -

RSiC plate Slab Board

$15.00 -

NSiC Tube Pipes by Nit

Inquiry -

used excavator hudraul

$16600.00 -

NSiC Thermocouple Prot

Inquiry -

Stalk Riser Tube for L

Inquiry -

NSiC Ceramic Heater Pr

Inquiry -

RSiC NSiC Ceramic Kiln

Inquiry -

used excavator hudraul

$11500.00

Product parameters

- brand:

- RXVAL

closure

This shop is operated by agent

- Set up shop

- Authorized by Manufacturers & Suppliers online marketplace B2B platform GongWong.com, can provide agency service

- Service Introduction

- Authorized product, Internet cloud promotion service integrating certification promotion and procurement inquiry

- Intelligent website construction

- PC terminal + mobile terminal, create a cost-effective corporate website!

closure